|

| April 23, 2019 | Volume 15 Issue 16 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Ford says supercomputers, 3D printing are secrets behind Mustang Shelby GT500 high performance

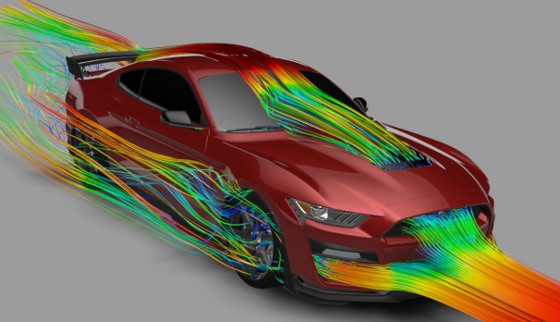

When the 2020 Shelby GT500 goes on sale later this summer, it will be the quickest accelerating, most aerodynamically advanced street-legal Mustang ever, thanks to virtual testing in supercomputers and 3D printing.

Borrowing best practices from more than a century of racing, Ford Performance designers, powertrain specialists, and aerodynamics engineers functioned as a virtual racing team to test hundreds of designs both digitally and physically. They used state-of-the-art digital and additive manufacturing prototyping tools as part of a mission to make the ultimate, most advanced performance street-legal Mustang ever.

"We created and studied designs among the engineering teams and proved out different strategies long before we built our first prototype cars," says Matt Titus, Ford Performance vehicle engineer. "Not only did this improve the effectiveness of the designs, it dramatically reduced the time it took to develop the GT500 -- and the costs associated with that."

Ford relied on 3D printing as a major prototyping tool, with many parts suitable for test and fit in a matter of days.

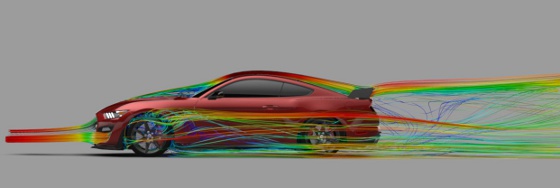

Every millimeter counts for the Mustang Shelby GT500 to deliver on downforce, braking, and cooling targets. The team leveraged Ford's vast resources of advanced design simulation tools and facilities, including the Ford Performance technical center in Concord, NC, and rapid 3D prototyping systems at its Advanced Manufacturing Center in Redford, MI. To physically validate the improving designs, Ford's wind tunnels in Michigan and Windshear rolling wind tunnel in Concord were also used.

Real-world testing still matters, so the Shelby GT500 team ran extended high-speed tests on some of the most notable racetracks across the United States -- including Virginia International Raceway, NOLA Motorsports Park, and GingerMan Raceway -- to refine the aerodynamic designs and help the all-new Shelby GT500 deliver the fastest track times ever in a production Mustang along with improved driver control for greater confidence behind the wheel.

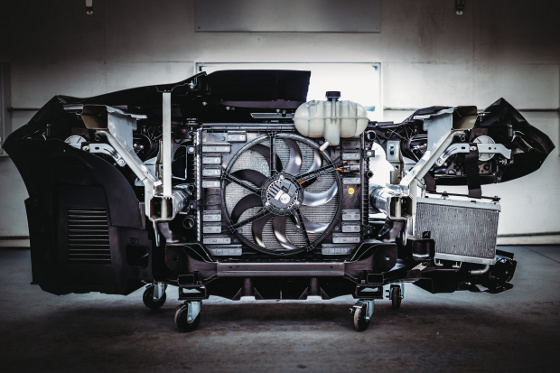

Delivering more than 700 hp using 93-octane fuel, maximizing cooling at the front is critical to the Shelby GT500's vigorous track performance, and it's where the team focused much of its efforts. At wide-open throttle, the cooling system needs to extract up to 230 kW of heat energy -- that's enough to heat a dozen homes. The massive front brakes reject another 100 kW of heat at maximum braking, so the team utilized advanced 3D airflow modeling to maximize overall cooling while working to minimize impact on front-end lift and drag.

More than 500 3D cooling and aerodynamic designs were analyzed to maximize aero performance and cooling, with more advanced design models driven on full-chassis simulators at the Ford technical center with professional racing drivers. Key modeling simulations included cooling systems, front fascia, and splitter designs, along with brake ducting, rear spoiler designs, and a large 6.03 sq-ft louvered hood vent.

Speeding development time, the most promising designs were printed in a matter of days, not months, allowing the team to increase the fidelity of performance and aerodynamic refinement. For example, more than 10 front splitter wickers were printed and tested, some with minute modifications to perfect their design, with multiple versions of parts simultaneously sent out for track evaluation.

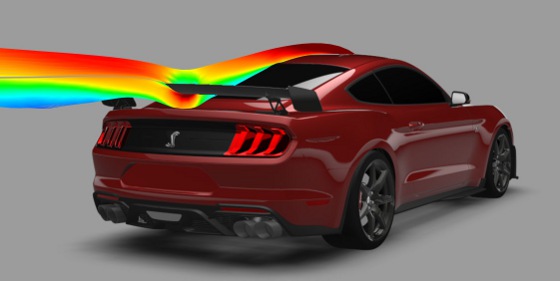

The team achieved maximum rear downforce of 550 lb at 180 mph, leveraging the Mustang GT4 race-proven rear track wing to deliver the most downforce ever on a street-legal Mustang with available Carbon Fiber Track Package. An innovative new rear spoiler design, standard on the base 2020 Shelby GT500 and known by the aero team as "the swing" -- a hybrid between a spoiler and a wing -- is the result of the advanced simulations and prototyping process. With available Handling Package and Gurney flap installed, the swing works to deliver 379 lb of rear downforce at 180 mph.

Keeping cool and precise on the track

High-performance cooling targets also factored into the design and virtual testing to help ensure consistent heat management and power delivery over extended sessions at the track. This included a new performance fascia design that doubles the front opening volume and increases cooling pack airflow through six heat exchangers at top speed by 50 percent versus the existing Mustang GT350 design.

2020 Shelby GT500 display front.

A removable rain tray further aids cooling and works to reduce underhood air pressure at high speeds, while a Shelby-specific rear diffuser helps channel under-car airflow.

A new dual-side thermostat routes coolant to a new auxiliary radiator, and a 600-W brushless electric fan motor and performance aero fan shroud with 16 speed flaps improves cooling pack airflow while mitigating drag and front-end lift. Two new race-style oil and transmission coolers further improve powertrain cooling.

Front cooling view.

Back cooling view.

"This all-new aero design merges state-of-the-art design and materials technology with the craftsmanship of Ford racing expertise to create the most aero-capable Mustang ever," says Steve Thompson, Ford Performance vehicle dynamics engineer. "It's powerful, balanced, and consistent -- even over extended track runs -- which works to deliver more fun and greater confidence for drivers."

Capable of mid-three-second 0-60 mph and sub-11-second quarter-mile scores, Shelby GT500 owes a lot of its impressive new attributes to tech transfer from Ford GT and Mustang GT4 racing programs. It features a first-in-class 7-speed dual-clutch transmission.

Other weight-saving and power-inducing measures include:

- Shelby GT500 starts with a supercharged 5.2-liter aluminum alloy engine built by hand. To keep the intake air cooler and deliver a lower center of gravity, the team inverted a 2.65-liter roots-type supercharger with air-to-liquid intercooler tucked neatly in the V8 engine valley.

- Like Shelby GT350, the aluminum alloy block features weight-saving wire-arc cylinder liners and high-flow aluminum cylinder heads, plus larger forged connecting rods and improved lubrication and cooling passages. Beneath that, a structural oil pan adds strength, reduces vibration, and features a patented active baffle system to keep oil where it's needed.

- Shelby GT500 also takes advantage of revised suspension geometry, a new electronic power steering unit, and lighter-weight coil springs front and rear. Next-generation active MagneRide suspension is included, along with the latest in advanced drive-mode technologies from Ford Performance. The payoff: the highest-ever lateral acceleration from a Mustang for greater track performance and driver control.

- No rear seat. (Well, that was easy!)

VIDEO

Source: Ford Motor Co.

Published April 2019

Rate this article

View our terms of use and privacy policy